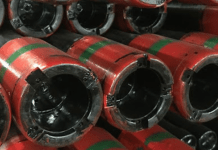

The wall thickness of sch 40 wal pipes plays a significant part in deciding their weight, holding noteworthy significance over assorted businesses dependent on pipes for different purposes. Whether for giving basic bolster in development ventures, facilitating liquid transportation in plumbing frameworks, or serving other basic applications, the weight of Schedule 40 pipes straightforwardly impacts their reasonableness and execution.

In development and foundation projects, the weight of pipes impacts their capacity to bear structural loads and withstand outside powers. Engineers must carefully select pipes with suitable divider thicknesses to guarantee the soundness and judgment of buildings, bridges, and other structures. Heavier pipes may require additional reinforcement and bolster to preserve their auxiliary astuteness and avoid spills or disappointments.

Examining the Connection between Pipe Weight and Schedule 40 Wall Thickness

To ensure that the proper channels are chosen and established for specific applications, engineers, designers, and manufacturers must have a fundamental understanding of the link between sch 40 wall thickness and pipe weight.

Divider Thickness

Schedule 40 pipes are characterized by their particular divider thickness, which specifically impacts their weight. Thicker dividers result in heavier channels, whereas more slender walls lead to lighter pipes. The thickness of the pipe dividers is decided based on the weight rating and application necessities.

Diameter

The external distance across (OD) of the pipe moreover plays a critical part in deciding its weight. By and large, bigger distances across channels have more material and subsequently weigh more than smaller distances across channels with the same divider thickness.

Material Thickness

The thickness of the material utilized in pipe manufacturing affects its weight. Common materials for Schedule 40 pipes incorporate carbon steel, stainless steel, and different amalgams, each with its possess thickness. Carbon steel, for case, features a lower thickness compared to stainless steel, coming about in lighter channels for the same measurements.

Coordinate Proportionality

The relationship between wall thickness and pipe weight is for the most part direct. As the divider thickness increments, the weight of the pipe increments relatively. Alternately, lessening the divider thickness diminishes the pipe’s weight.

Weight Calculation

The weight of a Schedule 40 pipe can be calculated employing a formula that takes into consideration its measurements (external breadth and divider thickness) and the thickness of the fabric. By duplicating the cross-sectional zone of the pipe by the length and the material thickness, the weight of the pipe can be determined.

Building Contemplations

Pipe weight may be a basic calculation in designing design, particularly in applications where pipes are subjected to different loads, weights, and natural conditions. Engineers must carefully assess the weight of pipes to guarantee they meet auxiliary prerequisites and security measures.

Auxiliary Back

In development and foundation ventures, the weight of pipes impacts their appropriateness for supporting structural loads. Engineers must select channels with fitting divider thickness and weight to guarantee the basic astuteness and solidness of buildings, bridges, and other structures.

Liquid Transportation

In businesses such as oil and gas, water conveyance, and plumbing, the weight of pipes influences their capacity to transport liquids productively and securely. Overwhelming channels may require extra bolster and fortification to resist pressure and prevent auxiliary disappointment.

Installation and Handling

The weight of pipes moreover impacts their ease of establishment and dealing with on-site. Heavier channels may require specialized gear and apparatus for lifting, situating, and establishment, including the overall cost and complexity of the extend.

Cost Contemplations

Pipe weight specifically impacts material costs, transportation costs, and enrichment costs. Lighter channels may offer fetched investment funds in terms of fabric obtainment and transportation, but heavier channels may be required to meet particular execution and security necessities.

Conclusion

The wall thickness of Schedule 40 pipes may be a basic figure affecting their weight, which in turn influences their appropriateness for different applications. Engineers, creators, and producers must carefully consider the relationship between wall thickness and pipe weight to guarantee ideal execution, auxiliary astuteness, and cost-effectiveness in differing mechanical and commercial projects.