What are Some Potential Future Improvements in Fecon Teeth Design that Might Enhance Mulching Efficiency?

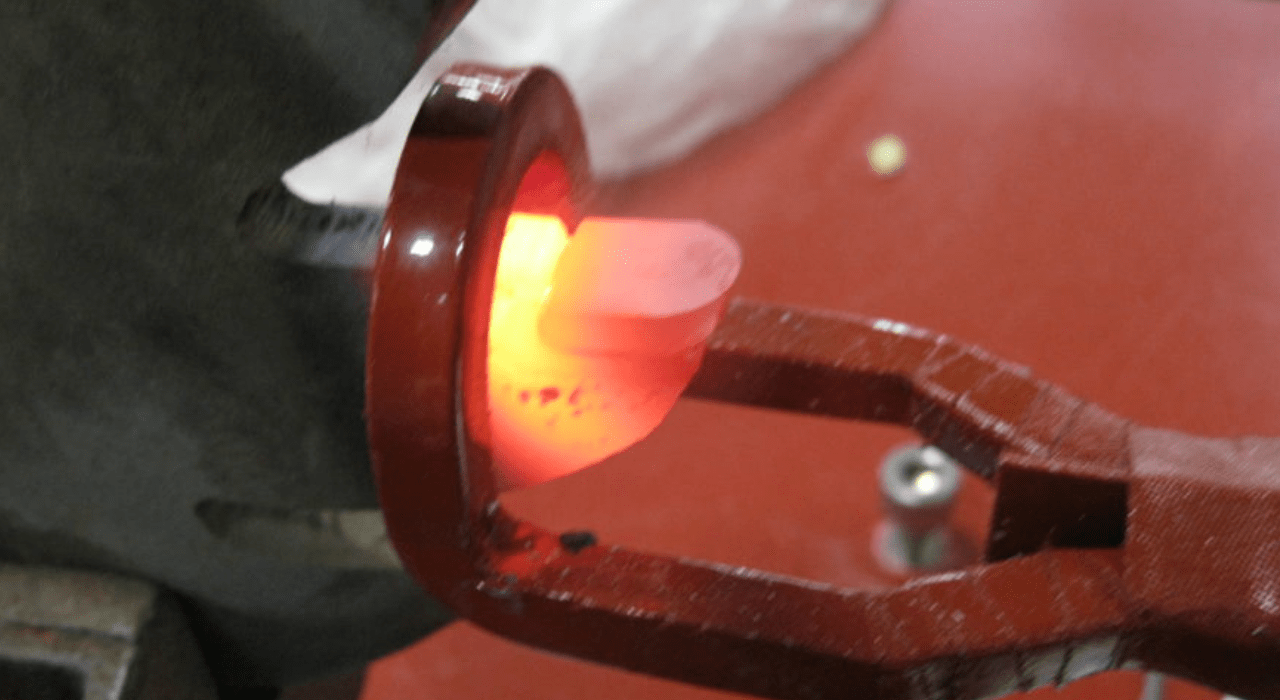

The right Fecon teeth layout generally features wonderful tungsten carbide construction with a durable and sharp cutting part. The fecon teeth are engineered for premiere-reducing performance and longevity, capable of handling hard flowers and abrasive situations.

They strike stability by putting on resistance and reducing performance, making sure of minimum downtime and decreased maintenance costs. Advanced designs may include self-polishing functions or specialized coatings to beautify sturdiness in addition.

The design prioritizes eco-friendly material processing, contributing to excessive productiveness in land clearing, forestry operations, and plant life control duties. Fecon mulcher Teeth are essential for the effective operation of mulching machines, and advancements in their layout ought to drastically beautify mulching performance.

Key Future Improvements in Fecon Teeth Designs

Here are some potential future enhancements in Fecon Teeth design that would cause higher performance, sturdiness, and operational performance:

Self-Sharpening Teeth

Self-sharpening teeth are designed to keep their slicing part automatically as they wear down. This feature might hold the Teeth sharp without the need for guide polishing, thereby preserving high slicing efficiency during their lifespan. Self-sprucing teeth ensure that the reducing part remains sharp, imparting regular mulching performance and lowering the need for frequent protection. Teeth will be designed with a hardness gradient, wherein the outer layer is harder than the internal middle, promoting self-sprucing as the outer fabric wears away.

Advanced Composite Materials

The usage of advanced composite materials in Teeth design can enhance durability and put on resistance. These materials ought to include bolstered ceramics, high-power polymers, or metal matrix composites. Composite materials can offer advanced wear resistance and toughness in comparison to traditional carbide or metal, extending the lifespan of the Teeth. Teeth ought to have edges bolstered with composite substances for more suitable slicing performance.

Modular Teeth Design

Modular Teeth designs allow for smooth alternatives of character components in preference to the entire Teeth. This modularity might allow operators to update the worn elements, lowering waste and charges. Modular designs decrease the replacement charges with the aid of permitting the reuse of components that are nevertheless practical. Teeth could feature interchangeable reducing inserts that can be changed without removing the complete teeth.

Better Teeth Geometry

Innovations in Teeth geometry should enhance the slicing performance and decrease resistance, thereby improving the mulching technique. This consists of optimized shapes, reducing angles, and surface textures. Optimized geometries can reduce the force required for slicing, improving the device’s overall performance. Advanced geometries may be tailored for precise vegetation kinds and conditions, increasing the adaptability of the mulcher. Textured surfaces can enhance fabric grip and reduce slippage throughout reducing.

Smart Sensors and Tracking

Integrating smart sensors into Teeth may want to offer actual-time statistics on put-on and overall performance, enabling proactive renovation and optimizing mulching operations. Sensors can monitor put-on degrees and alert operators whilst Teeth want a replacement, preventing sudden disasters. Historical statistics from sensors can manual future improvements in Teeth layout and material choice. Use sensors to collect statistics on cutting pressure, vibration, and temperature, imparting insights into Teeth’ overall performance.

Eco-Friendly Materials and Coating

Developing eco-friendly materials and coatings for Fecon Teeth can lessen the environmental effect of manufacturing and disposal at the same time as retaining high performance. The use of biodegradable or recyclable substances reduces environmental impact. Environmentally pleasant designs can assist meet regulatory necessities for sustainable practices. Increase coatings that don’t launch dangerous materials at some stage in put on or disposal.

Ending Lines

Future enhancements in the Fecon mulcher Teeth layout, which include self-sharpening features, superior composite substances, modular designs, superior geometries, smart sensors, and eco-friendly options, maintain the ability to seriously increase mulching efficiency. These improvements can lead to higher performance, decreased upkeep, price savings, and a lower environmental footprint, in the long run making Fecon mulching machines more effective and sustainable gear for land management and flower control.